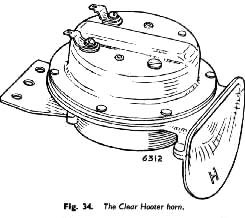

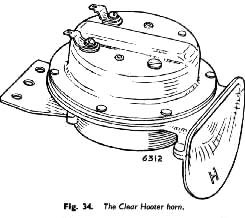

Clear Hooter horns (Refer to Fig. 34.)

The tonal quality of horns and their correct current consumption is accurately set before each unit leaves the manufacturers, therefore, the need for further adjust-ment after the horns have been fitted to the vehicle should not normally be necessary. However, in an Instance where a single or both horns fail to operate satisfactorily the exact cause can be quickly diagnosed and rectified as follows

Note—Early model horns can be dismantled for the purpose of examining the internal connections and contacts only, further dismantling beyond this is not to be attempted. Later model horns are a riveted assembly and, therefore, cannot be dismantled. If the horns are removed from the vehicle for the purpose of tonal adjustment, they are to be held firmly in a vice by the mounting bracket so that the best results in sound are obtained.

Sound—loss of volume

Normally this condition is caused by Insufficient current being drawn by the defective horn in which case the adjusting screw Is to be rotated slowly clockwise until the volume of sound is restored, then rotate the adjusting screw slowly anti-clockwise to the point where the volume of sound is just maintained. At no time should the operating current exceed 5 amperes.

Intermittent operation

Usually this cause can be attributed to that of mal-adjustment or the presence of foreign matter between the contact points. In this instance the adjusting screw is to be rotated slowly in a clockwise direction for almost one half turn. Should the horn fall to sound after carrying out this adjustment the screw is to be rotated in the reverse direction until the horn operates at the

|

correct volume, which should occur within 180 degrees either side of the original setting.

Complete failure of sound

In the event of a complete failure, examine the appro-priate fuse and the electrical connections in the horn circuit it for security and carry out a voltage check to esta6lish whether the correct voltage is available at the horn terminals. If it was observed that a gradual deterioration in volume was apparent before the failure then the instructions outlined under the heading “Sound

—loss of volume” are to be carried out. Should the horns have been operating satisfactorily prior to a sudden failure, the horn circuit is to be checked in order to establish the current capacity, should this be in excess of 5 amperes, the adjusting screw is to be rotated slowly in an anti-clockwise direction until the horns are restored to their correct volume of sound. If the current capacity is less than that specified the adjusting screw is to be rotated slowly in the reverse direction until the correct volume is obtained.

|

**

**