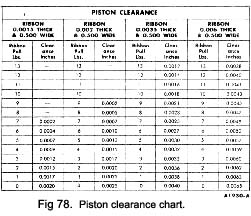

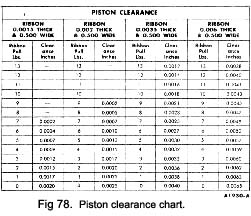

8. Knowing the ribbon thickness and the actual pull required, the piston clearance can be determined by referring to Fig. 78.

Example.—lf a 5 pound pull on the scale is required with a 0.002 in. ribbon, then the clearance between the piston and cylinder bore is 00012-in.

9. If the reading on the scale is greater than the pull shown in Fig. 78, check the piston for any damage that may effect the pull reading. If no damage is evident, try another piston. Check the fit 6f the new piston.

Each piston thus fitted should immediately be marked with the respective cylinder number.

It is recommended that the clearance between the fitted piston and cylinder wall be held to the mean limit. The minimum and maximum clearances shown in the specifications pertain only to the fitting of a new piston in a new bore. The wear limit specification is only to be used as an allowable limit when fitting a used piston in a used bore.

5. Loosen the generator mounting bolts at the genera-tor. Remove the generator support bolt at the water pump.

6. Remove the fan, spacer, pulley and drive belt.

7. Remove the radiator.

8. Remove the crankshaft pulley from the crankshaft vibration damper. R Piston weight Piston weight

All pistons are the same weight, both standard and oversize ; therefore, various sizes of pistons can be used without upsetting engine balance.

Fitting piston rings

1. Select the proper ring set for the size piston to be used.

2. Position the ring in the cylinder bore in which it is going to be used.

3. Push the ring down into the bore area where normal ring wear is not encountered.

|

4, Use the head of a piston to position the ring in the bore so that the ring is square with the cylinder wall. Use caution to avoid damage to the ring or cylinder bore.

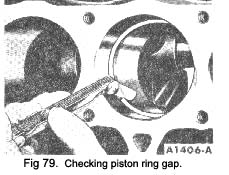

5. Measure the gap between the ends of the ring with a feeler gauge (Fig. 79). If the ring gap is less than the recommended lower limit, try another ring set.

6. Check the ring side clearance of the compression rings with a feeler gauge Inserted between the ring and its lower land (Fig. 80). The gauge should slide freely around the entire ring circumference without binding. Any wear that occurs will form a step at the inner portion of the lower land. If the lower lands have high steps, the piston should be replaced.

Fitting piston pins

The piston pin to piston should be a light thumb press fit at normal temperature (700F). Refer to the Data Section under “Gudgeon Pin” for the piston pin dimension.

|

**

**

Piston weight

Piston weight