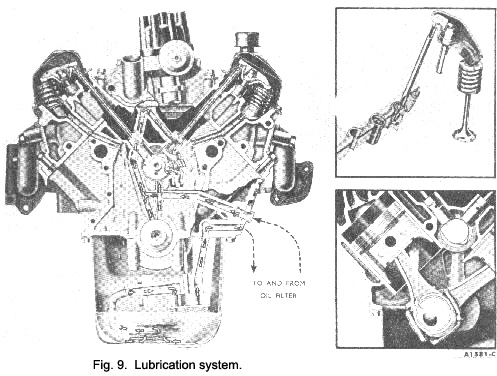

Lubrication system

Oil from the oil pan sump, located in the front of the oil pan, is forced through the pressure-type lubrication system (Fig. 9) by a rotor type oil pump. A spring-loaded relief valve in the pump limits the maximum pressure of the system. Oil relieved by the valve is directed back to the intake side of the pump.

All the oil discharged by the pump passes through an exclusive design full flow-type filter before it enters the engine. The filter is mounted at the lower left front of the engine.

On a disposable-type oil filter, a relief valve in the filter permits oil to bypass the filter if the element becomes clogged.

On a replaceable element-type oil filter, a bypass in the centre bolt provides oil to the engine in case the filter element becomes clogged. The by-pass is located in the hollow centre bolt of the filter and consists of a spring-loaded valve. When the element is clean and oil will flow through it, the pressure difference between the -

|

inner and outer faces of the valve is not great enough to overcome

the spring pressure behind the valve. There-fore, no oil flows

through the bypass. When the element is dirty and will not permit

a sufficient flow of oil, the pressure acting on the inner face

of the valve drops. If the pressure difference between the valve

faces is great enough to overcome spring pressure, the valve

will open.

Oil then bypasses the element, maintaining an emergency supply of oil to the engine.

From the filter, the oil flows into the main oil gallery which is located to the right side of the camshaft. The oil gallery supplies oil to each individual main bearing, through drilled passages in the block. Passages are drilled from each main bearing to each camshaft bearing. Number I main bearing feeds No. I camshaft bearing, and No. 2 main bearing feeds No. 2 camshaft bearing, etc. The oil then flows through notches or grooves in the main bearings to lubricate the crankshaft Journals. The timing chain and sprockets are lubricated by oil deflected from the front camshaft bearing by an oil drip trough on the cylinder front cover.

|

**

**